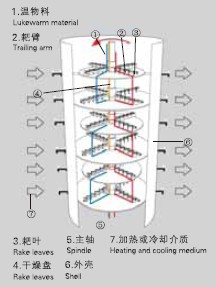

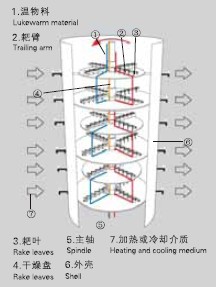

Application:

It is especialized for drying and cooling powder materials like medicinw, agraculture medicine, chemical industry, foodstuff, feedstuff and so on.

(一)Organic chemical industry: Polyvinyl chloride, teflon resin, fumaric acid, anthraquinone, nitroanthraquinone, amino phenol, melamine, cyanogen uric acid, amino benzene xanthognic acid, antioxidant 168, color phenol AS, stearate, aniline, nitrophenylamine, double pentaerythritol, chlorination paraffin wax, calcium formiate, three ethylene diamidogen, benzene sulfinic acid sodium, benzene.m. dicarboxylic acid, dimethyl ester pentathionic acid sodium, thiourea, oil soluble aniline black dyestuffs, erie black dye and so on organic industrial chemicals and intermediate.

(二)Inorganic chemical industry: Light quality calcium carbonate, active calcium carbonate, nanometer level superfine calcium carbonate, magnesium carbonate, aluminum hydroxide, white carbon black, strontium carbonate, barium carbonate, carbonic acid armor, lithopone, insurance powder, potassium sulfate, microballoons catalyst, magnesium hydroxide, cupric sulfate, nickel sulfate, nickel sour ammonium, sodium molybdate, sodium chloride, potassium chloride, calcium chloride, sodium fluoride, cryolite, oxidized iron oxide red, lithium hydroxide, nickelous hydroxide, zirconium hydroxide, calcium carbonate, sulfur and so on.

(三)Medicine, food: Ammonia animal pen penicillin, Deng Yan, laevo-rotatory benzene glycine and intermediate, spore ammonia sai, spore three qin, An Naijin, west onamot for bulk drugs and medicine intermediate and so on Ding, Vitamin b, Vitamin c, for medicinal purposes leaning magnesium silicate, caffeine, tea, flowered extraction, gingko leaf, chocolate powder, starch, corn embryo tooth bud.

(四)Feed, fertilizer: The potassium carbonate, the biological potassium fertilizer, the protein feed, the feed use the aureomycin, the bran, the distiller's grain, the grain, the weed killer, the cellulose, the feed calcium hydrogen phosphate and so on.